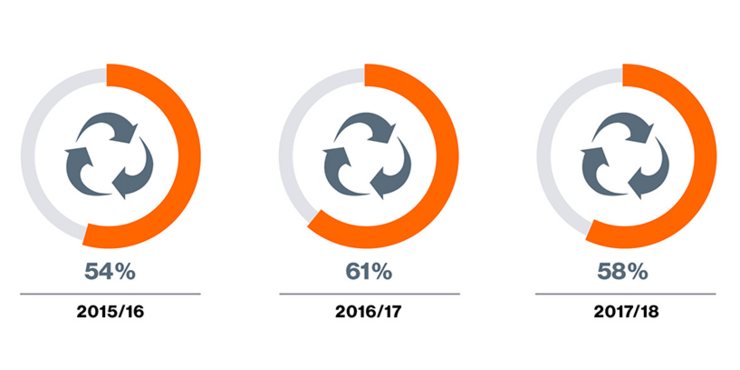

Responsible handling of raw materials

At the uvex sports group’s plants in Lederdorn and Nyrsko, a process has been introduced to dispose of, sort and recycle plastic waste. Bernhard Preis, commercial manager at uvex sports Lederdorn, and Stefan Schimpe, logistics/training uvex sports Lederdorn, on the background to the project:

How did the idea come about to return waste and raw materials to industrial operations?

Bernhard Preis: The injection moulding process always produces a lot of waste. A suggestion came from the workforce in 2014 to think about what we could do with this plastic waste. We obtained professional support from a waste disposal and recycling firm in the region. It then proved useful at uvex sports Lederdorn to introduce a process to separate the waste before it was sent for recycling.

What is the process like in detail?

Stefan Schimpe: Our concept for the Lederdorn plant involved us introducing collection points with containers to separate the different kinds of waste. There are cards explaining in detail what should go where. Here, plastics and product parts such as helmet shells are shredded and fed back into industry again, for example. This way, a lot of waste can be reused as a valuable raw material. Of course, there is also a part that remains that cannot be used again and has to be disposed of.

How much work did introducing the system on the site involve?

Bernhard Preis: The system was received very positively and quickly by employees following a training session and a few weeks of changeover. It’s a bit like separating household waste at home. Because the concept has proved successful, we also launched it at our extended workbench in Nyrsko in 2016.

Stefan Schimpe: Here, waste such as plate materials, foam, cardboard, sheet metal and textiles are also produced, which are disposed of and recycled via the same recycling specialists. The process has paid off from an economical perspective. The cost of professional recycling is still less than the cost of disposal prior to 2014 – a win-win situation for our plants and the environment.

BSA Obernzell

In the 2017/18 financial year, the BSA production site in Obernzell, Germany, successfully implemented a new plant concept for manufacturing foam helmets for skiing, cycling and riding. These machines have been commissioned as part of an expansion of the machine park, which was prompted by an increase in unit numbers. Using these machines achieves energy savings of 20 to 25 percent per new machine compared to a conventional machine. An expansion of the machine park, and thus further investment in on-site technology, is in the pipeline.